As the concept of circular fashion has gained traction, researchers and entrepreneurs are developing tools they hope brands will implement to finally close the loop. One of the latest is new AI sorting technology developed by California-based company Refiberd.

Improved sorting will be central to transforming how the fashion industry deals with waste, experts agree. “Recycling textiles is more complicated than recycling yoghurt containers because textiles incorporate so many material blends,” says Rachel Kibbe, founder of CSG and policy coalition at American Circular Textiles group (ACT). “In order for recycled fashion to become the norm, the cost of producing recycled textiles in our apparel, footwear and accessories will need to achieve price parity with virgin materials. Efficient and accurate textile sorting is a critical missing link to cost-effectively scaling circularity efforts.”

That’s where Refiberd hopes to make an impact. The company, founded in 2020 by engineers Sarika Bajaj and Tushita Gupta, last month announced $3.4 million in seed funding (in a round led by venture capital fund True Wealth Ventures) to scale its AI-enabled sorting technology for textile-to-textile recycling.

Currently, less than 1 per cent of fibre used to produce clothing is recycled to make new garments, according to the Ellen MacArthur Foundation; most textile waste ends up in landfill, on the desert in Chile or the beaches in Ghana. The process of turning this waste into new material requires a seamless infrastructure and collaboration between supply chain actors, from collection to sorting, pre-processing and recycling — and that infrastructure doesn’t currently exist at scale.

This is set to change as new incoming legislation forces behavioural change and paves the way for more startups who can provide solutions. Legislators are working on a bill proposed in California that could become the first in the US to require brands to finance clothing waste management programmes. The European Union has set a tough deadline of 2025 for mandatory waste collection of textiles, rather than sending them to landfill.

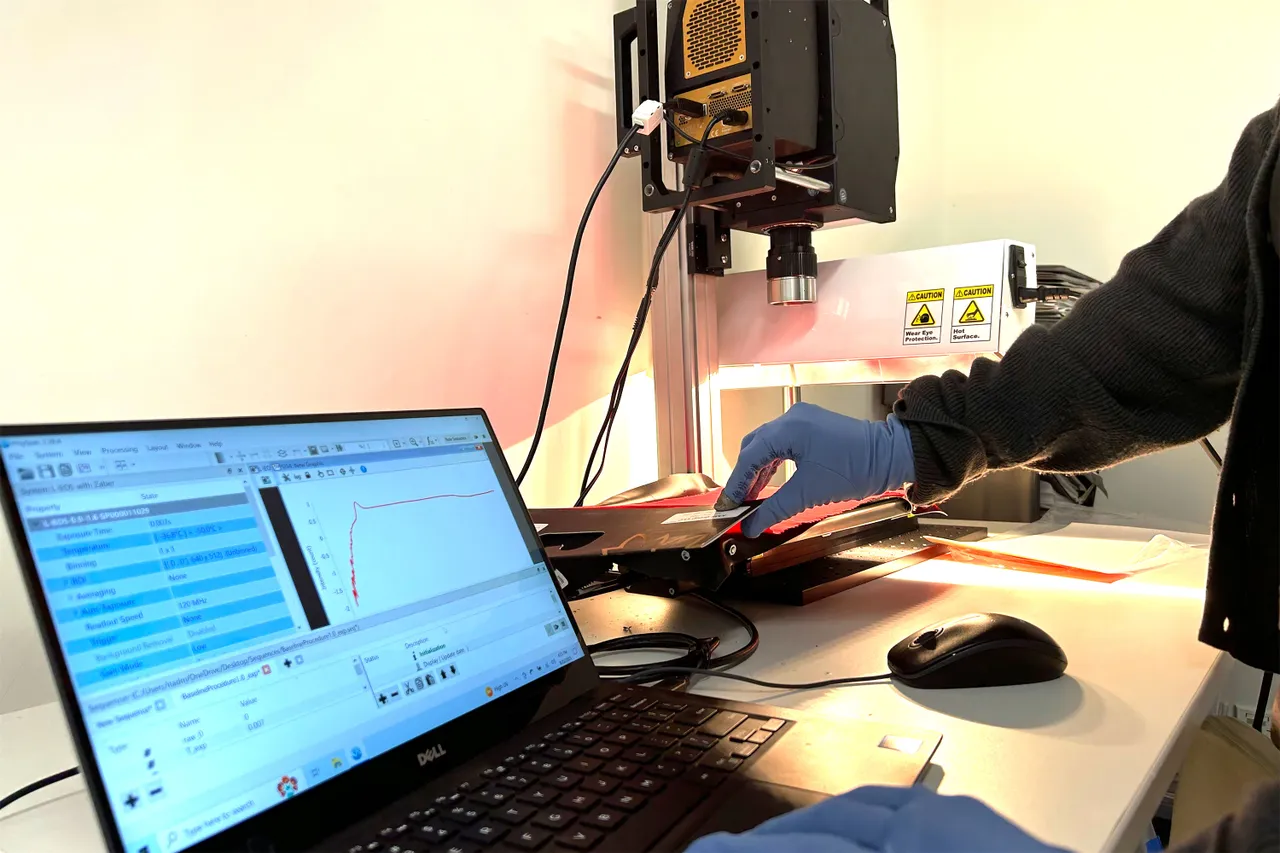

Refiberd is not the only company exploring this relatively new field. Other players operating in the space include Siptex, Fibersort, Tomra, Matoha, TrinamiX, Sortile and Picvisa. Bajaj says what sets Refiberd apart is its use of a hyperspectral camera, which collects and processes information from across the electromagnetic spectrum (and can therefore see a multitude of information that is invisible to the human eye). This information is fed into a machine learning model, which determines the material composition of the textile.

“That gets us extra data, alongside machine learning that identifies attributes beyond fibre composition, such as garment type and colour,” Bajaj explains. “You’re able to get down to a level of fidelity that was never possible before — which will increase confidence metrics that enable sorting.”

That expertise led to Refiberd being chosen for innovation platform Fashion for Good’s 2022 Global Innovation Programme. “This pioneering innovation excels in accurately identifying fibre composition and contaminants, effectively tackling complexities like trace elastane and diverting feedstock to fibre-to-fibre recycling,” says Dolly Vellanki, innovation associate at Fashion for Good, which also took part in its recent funding round.

The H&M Foundation also believes it has potential, awarding Refiberd one of its prestigious 2023 Global Change Awards. “Refiberd and its AI sorting technology could be one of the critical keys to transforming the industry and closing the loop of textile waste in an unprecedented way,” says Christiane Dolva, the foundation’s strategy lead.

The importance of accuracy

There is a long way to go to achieve accurate textile sorting at scale, says Fashion for Good’s Vellanki. “Currently, sorting processes lean heavily on manual methods. However, manual sorting falls short for recycling, particularly for high-quality mechanical and chemical processes that necessitate fibre and colour identification.”

Accuracy of analysis is the big must-have. “We’re seeing a greater and greater need to have really strong identification of materials in textile waste,” says Refiberd’s Bajaj. “Previous technologies would give you a ballpark range which might be a five to 10 per cent tolerance, but it’s to the same level of a human guessing what it is by feeling it. [A human] wouldn’t be able to tell you, ‘Oh there’s 2 per cent spandex contamination’ [referring to the elastane used by many brands to achieve stretch] — which matters a lot to recyclers [because] it could have a chemical effect that they can’t control in their own process.”

The lack of precision in analysing material fibre composition is a key obstacle to reusing and recycling textile waste. Most mechanical recyclers can only process waste that has more than 95 per cent cotton content, according to Refiberd, while chemical recyclers source poly-cotton blends with less than 5 per cent spandex.

“You can imagine a system that only uses cotton. You put in polyester and that’s going to melt round the shredder — all of a sudden you’re out of commission and you’ve destroyed a million-dollar machine,” says Bajaj of Refiberd, of the precautions currently necessary in the recycling industry.

In 2022 the Sorting for Circularity framework, initiated by Fashion for Good and Circle Economy, found that 494,000 tonnes, or 74 per cent of low-value post-consumer textiles, are available for closing the loop within Europe’s clothing and textiles sector. Refiberd believes its technology could help more than half of this to be recovered.

“It looks like at least 50 to 70 cent of the textile waste that we do see could go into a recycling stream,” says Bajaj. “Maybe 30 per cent is still unrecyclable, where it’s like a very complex blend of spandex or nylon… But, you can capture that bigger bucket. As recycling technologies improve, then that percentage only gets higher and higher.”

Recycling hurdles

While Refiberd’s technology holds promise, there are big challenges to overcome on the path to circularity.

“In addition to sorting, the industry needs trackable collection of individual garments, processing capabilities to turn finished garments into recyclable material components, and additional fibre-to-fibre recycling technology,” says Stuart Ahlum, co-founder and COO of SuperCircle, a tech and reverse logistics platform specialising in recycling logistics and textiles processing. “The infrastructure around trackable collection and garment processing, however, is still nascent. Most market solutions are manual and incredibly inefficient.”

With a platform that addresses trackable collection at the garment level, SuperCircle is aiming to improve the process. “We provide the operational technology to drive sortation and the ability to process finished garments into usable material feeds that we can send to our recycling partners,” says Ahlum.

Logistics and infrastructure aside, there is also still a lot of clothing that defies recycling entirely, a reminder that the system as a whole is in urgent need of an overhaul. “There are many fibres in circulation which cannot be recycled or are limited in the number of times they can be recycled. We need an expanded range of solutions so that all fibres are recyclable,” says Stacy Flynn, CEO of Evrnu, a Seattle-based textile recycling startup.

Garment construction is a factor, too. “Pre-processing activities and infrastructure must be advanced to tackle hurdles like the removal of disruptors such as buttons and zippers, while preparing items for recycling xthrough processes like shredding and cleaning,” adds Fashion for Good’s Vellanki.

Every step counts, though, and the team at Refiberd is encouraged by the current momentum. “People can really get to the point of sorting textile waste and sending it to a recycler,” says Bajaj. “We’re seeing the first circular loops truly start.”

Comments, questions or feedback? Email us at feedback@voguebusiness.com.